Chinese Chemical Manufacturer – The Development Path of Foconsci Chemical

Foconsci Chemical has been deeply engaged in the chemical manufacturing industry for fifteen years and is often asked, “Are chemical plants today still as dirty, messy, and noisy as they once were?” Whenever this question arises, company staff always lead visitors to the plant’s observation deck—an area that once housed old reactors and now offers a clear view of the vibrant landscape of finless porpoises swimming in the waves. Over the past decade, this company has reshaped the development of China’s chemical manufacturing industry, using technology as its pen and responsibility as its ink.

Looking back, “high energy consumption” was a label Foconsci Chemical couldn’t shake.

Before the 2018 technological upgrade, the distillation towers in its workshop consumed large amounts of steam daily, and the resulting exhaust required additional cost and effort to treat. The turning point came with in-depth collaboration with research teams from universities such as Shandong Jiaotong University. By introducing high-efficiency packing and guided composite tray technology, the company’s separation efficiency increased significantly by 40%. More notably, within three years of operation, this new technology system has helped the company save energy equivalent to 208,000 tons of standard coal and reduce carbon dioxide emissions by over 500,000 tons. Today, stepping into the workshop, the once over-ten-meter-tall reactors have been replaced with microfluidic field reactors, resembling “desktop factories.” Equipment just two or three meters tall can now accomplish the same production tasks, reducing energy consumption by 40%.

This technological breakthrough has given Foconsci Chemical a competitive edge in the market.

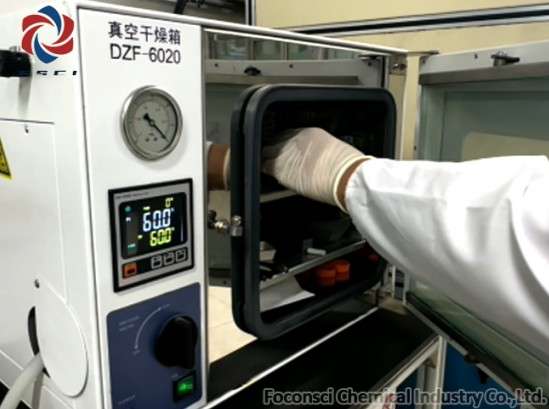

Beyond this, the company has shifted its focus toward fine chemicals and high-value-added products. Ranging from battery materials for new energy vehicles, to essential intermediates in pharmaceutical R&D, and high-performance polymers tailored for the aerospace sector, a suite of high-end products has gradually become a mainstay of the company’s business—accounting for nearly half of its operations. Underpinning this transformation is the company’s years of accumulated expertise in catalyst development, precision reaction control, and separation processes. Leveraging these technical reserves, Foconsci Chemical can precisely address customers’ customized needs and deliver tailored solutions. It is this professionalism and reliability that has enabled the company to gradually build a good reputation and deep trust among domestic and foreign customers.

As green development becomes a global consensus, Foconsci Chemical has also kept pace with exploratory efforts, continuing to invest in green chemical engineering and sustainable development. A visit to its production facilities reveals full-process monitoring across every link—from wastewater treatment and solvent recovery to energy management. The company has even introduced an AI prediction system, which optimizes production scheduling through data analysis to minimize raw material waste.

In the international market, Foconsci Chemical has demonstrated a proactive expansion stance. Company has established a rigorous quality management system, successfully obtained ISO 9001 and ISO 14001 certifications, and ensures its products comply with the EU’s REACH regulations. Foconsci Chemical has achieved direct cooperation with clients in Europe, North America, and Southeast Asia—strengthening the competitiveness of the “Made in China” label in the global chemical manufacturing sector.

Looking back at Foconsci Chemical’s development path, its growth is more than just a story of one company’s “solo effort”; it serves as a vivid microcosm of the transformation underway in China’s chemical manufacturing industry. The sector is gradually moving away from its past reliance on energy-intensive, low-value-added production models toward a direction driven by green practices, high-endization, and innovation. Once, chemical plants were often labeled as “dirty, messy, and substandard.” Today, however, companies like Foconsci Chemical are reshaping the industry’s image bit by bit—through technology empowerment, environmental initiatives, and a sense of responsibility—while opening up broader prospects for the industry’s future development.